In the world of heavy machinery and equipment, proper maintenance is key to ensuring smooth operations and extending the lifespan of your valuable assets. One crucial aspect of maintenance is dealing with leaks and preventing potential damage to components. This is where custom seal kits come into play. These specialized kits are designed to provide a perfect fit for your machinery, keeping it running efficiently and minimizing downtime. In this ultimate guide, we will explore everything you need to know about custom seal kits, from their importance to finding the ideal fit for your equipment.

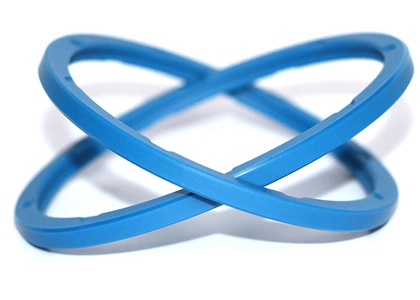

Seals play a critical role in protecting machinery from contaminants, reducing friction, and preventing leaks. Over time, regular wear and tear can lead to seal degradation, compromising the performance and reliability of your equipment. Custom seal kits are tailored to fit specific machinery models, ensuring optimal functionality and compatibility. By investing in high-quality custom seal kits, you can significantly reduce maintenance costs, enhance productivity, and avoid costly breakdowns.

Selecting the appropriate custom seal kit for your machinery requires a systematic approach. Here are some essential steps to ensure you find the perfect fit:

Different types of seals serve distinct purposes, such as hydraulic seals, pneumatic seals, and mechanical seals. Understanding the specific requirements of your machinery will help you identify the most suitable seal type.

Accurate information about your machinery is crucial for finding the right custom seal kit. Gather details such as make, model, year of manufacture, and serial number. This data will assist suppliers in providing the exact seal kit that matches your equipment.

The working environment plays a significant role in seal performance. Consider factors like temperature, pressure, exposure to chemicals, and potential abrasives in the operating environment. This information will help in selecting seals with appropriate materials and specifications.

Partner with reliable suppliers who have experience in providing custom seal kits for machinery. Look for companies with a track record of delivering high-quality products and exceptional customer service.

Investing in custom seal kits offers numerous advantages, including:

Custom seal kits are designed to match your machinery's exact specifications, leading to enhanced performance and efficiency.

Properly installed and maintained seals prevent leaks and reduce the risk of component damage, thus prolonging the life of your machinery.

Minimizing machinery downtime is crucial for maintaining productivity. Custom seal kits help in quick repairs and replacements, reducing downtime significantly.

By preventing leaks and reducing the need for frequent maintenance, custom seal kits result in substantial cost savings over the long term.

Once you have acquired the perfect custom seal kit for your machinery, proper installation and maintenance are essential for optimal performance:

Unless you have skilled personnel in-house, it's best to rely on professional technicians for the installation of custom seal kits. Proper installation ensures the seals perform as intended and maximizes their lifespan.

Schedule routine inspections to identify potential issues with the seals. Timely detection of wear and tear allows for proactive maintenance, preventing major breakdowns.

Proper lubrication is critical for the smooth operation of seals. Follow the manufacturer's recommendations for lubricant type and schedule.

Educate your maintenance team about the importance of custom seal kits and the best practices for their care. Knowledgeable personnel can ensure proper handling and maintenance of seals.

Custom seal kits are the unsung heroes of machinery maintenance, safeguarding equipment from leaks and contaminants. By following the guidelines in this ultimate guide, you can identify the perfect fit for your machinery, leading to improved performance, extended lifespan, and cost savings. Remember to partner with reputable suppliers and prioritize proper installation and maintenance for the best results. So, invest wisely in custom seal kits, and your machinery will thank you with years of trouble-free service. At Sanping, a trusted machinery parts factory, we specialize in providing high-quality sealing solutions, including the China piston seal, designed to enhance the performance and lifespan of your machinery. Our PC 200 travel motor seal kit is another example of our commitment to quality and precision, ensuring your machinery operates at its best. With products like the LBH seal and skeleton oil seal, we continue to set the standard for high-performance machinery components, contributing to the longevity and reliability of your equipment.

Travel Motor Seal Kit Fits PC200-5 Excavator

ROI Rotary Seal Fits Excavator

SPGO Piston Seal Fits Excavator